Long-lasting moisturization is the core demand for healthy lip care. Due to the lack of sebaceous gland protection, lip skin is prone to moisture loss and requires a complete care system of "hydration - moisture locking - repair" through lip balms. High-quality long-lasting moisturizing lip balms must be supported by high-active ingredients and scientific formula ratios. They can not only quickly penetrate to replenish lip moisture but also form a breathable moisture-locking film to reduce water evaporation, while repairing the damaged lip barrier. This achieves long-lasting hydration for over 8 hours, fundamentally improving lip dryness, tightness, peeling and other issues, and maintaining a healthy and plump lip condition.

Exclusive Brand Cooperation Channel: Custom OEM/ODM Services for Long-Lasting Moisturizing Lip Balms to Explore New Tracks in Lip Care Market

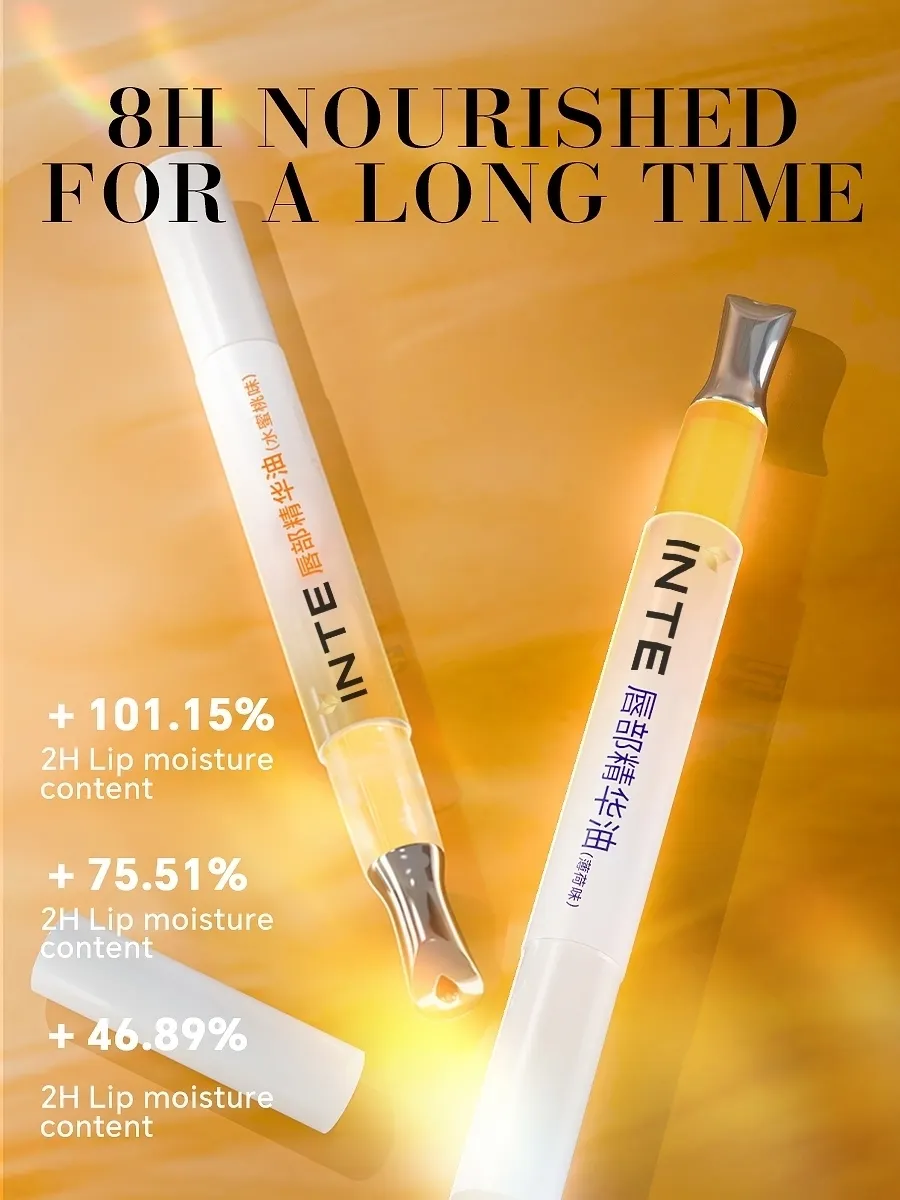

Leveraging its global-leading cosmetics OEM/ODM manufacturing capabilities, INTE Cosmetics provides full-chain customized services for long-lasting moisturizing lip balms to brands, distributors, and beauty salons. With ingredient innovation, technological upgrading, and flexible services, we empower partners to create differentiated products and seize the dividends of the lip care market.

Decoding Long-Lasting Moisturization: Core Technologies and Market Opportunities of Lip Balms

The core competitiveness of long-lasting moisturizing lip balms lies in breaking through the limitations of traditional moisturization and achieving the dual effects of "instant soothing + long-term nourishment". The achievement of this goal relies on two core technical supports: precise selection of ingredients and scientific formula ratio.

In terms of ingredient selection, priority should be given to high-active raw materials with dual functions of hydration, moisture locking and repair. For example, small-molecule hyaluronic acid can deeply penetrate to replenish water, while large-molecule hyaluronic acid can form a moisture-locking film on the lip surface; ceramides and peptides can synergistically repair the damaged lip barrier and enhance the skin's own moisture-locking ability; natural plant oils (such as shea butter and camellia oil) can improve product moisturization and extend the moisturizing effect. These ingredients must undergo strict screening to ensure purity and activity, laying the foundation for long-lasting moisturizing effects.

In formula ratio, it is necessary to build a "layered nourishment" system. By regulating the ratio and molecular weight of different ingredients, the organic combination of rapid hydration and long-term moisture locking is realized. At the same time, the formula should avoid irritating ingredients to ensure gentleness and no burden, suitable for various lip conditions. This is also the key for brands to establish differentiated advantages in the lip care market.

With years of technical accumulation, INTE Cosmetics deeply integrates ingredient selection, formula R&D and market demand, providing brands with full-process support from concept to mass production, helping to create long-lasting moisturizing lip balms with core competitiveness.

INTE Cosmetics: Three-Dimensional Empowerment for Long-Lasting Moisturizing Lip Balm OEM/ODM

1. R&D Empowerment: Precisely Creating Long-Lasting Moisturizing Formulas

INTE adheres to the core principle of "traceable raw materials" and has established long-term strategic cooperation with top global raw material suppliers. All raw materials meet EU standards, including core long-lasting moisturizing ingredients such as hyaluronic acid, ceramides, peptides, and natural plant extracts, ensuring product efficacy and safety from the source.

Backed by a team of over 40 professional researchers and the dual-core R&D philosophy of "Biotechnology × Natural Extracts", we have built a library of more than 3,000 efficacy-proven formulas. Targeting long-lasting moisturization needs, the R&D team has conducted a large number of in vitro tests and formula optimizations, precisely adjusting ingredient ratios to create a three-dimensional formula system of "hydration - moisture locking - repair", which can achieve long-lasting moisturization for over 8 hours. Meanwhile, we can assist brands in applying for 28-day human efficacy test reports and provide complete raw material traceability documents, offering authoritative data support for product marketing.

2. Production Empowerment: Standardization Ensuring Product Quality

The company has invested in building 100,000-class cleanrooms and 12 intelligent production lines, equipped with precision high-speed filling equipment and full-process intelligent control systems. This realizes fully automated production of lip balms, covering raw material processing, formula blending, filling and sealing, and finished product testing. It not only guarantees production efficiency but also avoids quality fluctuations caused by manual operations.

Quality control runs through the entire production chain, with 36 strict inspection checkpoints, fully complying with international certification standards such as ISO 22716, SGS, FDA, FEI, MSDS, SCNP, CPNP, and CN. From raw material purity testing, formula stability testing, to finished product microbial screening and moisturizing efficacy verification, each link has clear standards and traceable records, ensuring that every batch of products meets the high-quality standards of long-lasting moisturization, gentleness and safety.

3. Service Empowerment: Flexibly Adapting to Cooperation Needs

To meet brands' needs for rapid market response, INTE has launched an efficient and flexible cooperation service system: providing free sample support, completing the R&D and delivery of customized samples within 7 days to help brands quickly verify market feedback; in the mass production stage, committing to delivery within 28 working days to ensure products are launched in a timely manner to seize the market; supporting TT/LC payment terms to provide tailored financial solutions for different types of partners.

Service models cover diversified scenarios such as OEM, ODM, sample-based customization, and contract manufacturing. Whether it is full-process support for start-up brands or formula upgrading and mass production needs for mature brands, we can provide targeted services. Professional teams are assigned throughout the process to simplify communication procedures, reduce cooperation costs, and achieve efficient implementation.

Cooperation Empowerment System: Modular Processes to Quickly Open Up the Entire Product Launch Link

- Pre-demand Sorting: Launch the "1+N" docking model (1 dedicated project manager + N technical supports). Through standardized questionnaires and special seminars, comprehensively decompose brands' core needs for long-lasting moisturizing lip balms, such as efficacy thresholds, cost budgets, channel adaptation, and batch gradients, and form a demand conversion report that can be directly connected to R&D and production.

- Modular Solution Output: Based on the demand conversion report, provide a combined solution of "formula module + packaging module + production module". Each module includes more than 3 alternative schemes and pros and cons analysis, supporting brands to combine and adjust as needed. Simultaneously issue detailed technical parameter specifications and production feasibility evaluations.

- Sample Closed-Loop Testing: Complete the production of free samples within 7 days, and provide "raw material traceability samples + product efficacy test data + usage scenario test reports" along with the samples. Open an exclusive feedback channel to respond to sample adjustment needs within 24 hours until meeting the brands' expected standards.

- Standardized Cooperation Confirmation: Clarify the rights and responsibilities of both parties, refine production process standards, product acceptance indicators, logistics and distribution plans, payment terms (TT/LC), and the delivery list of certification documents. Sign a formal cooperation agreement including quality assurance and after-sales commitments to avoid cooperation risks.

- Transparent Mass Production Control: Build an exclusive cooperative visualization platform to synchronize production progress, quality inspection data, and raw material usage in real time. Set up an early warning mechanism for key nodes. The project manager issues a production progress report every week to ensure brands fully grasp the production dynamics.

- Post-Delivery Value-Added Services: Complete the delivery of finished products within 28 working days, and simultaneously provide complete test reports, raw material traceability files, and product usage guide manuals. Open a 3-month after-sales technical hotline to provide value-added consulting services such as formula fine-tuning and production process optimization, helping brands solve market feedback problems.

The lip care market continues to expand, and long-lasting moisturizing products have become a core growth driver. With R&D, production, and services as the three core capabilities, INTE Cosmetics provides cost-effective OEM/ODM solutions for long-lasting moisturizing lip balms to brands, distributors, and beauty salons. Whether you are deploying new product categories or upgrading existing products, you can quickly implement them with INTE's professional strength and establish differentiated advantages in the fierce market competition. We look forward to cooperating with you to win new opportunities in the lip care market!

Table of Contents

- Exclusive Brand Cooperation Channel: Custom OEM/ODM Services for Long-Lasting Moisturizing Lip Balms to Explore New Tracks in Lip Care Market

- INTE Cosmetics: Three-Dimensional Empowerment for Long-Lasting Moisturizing Lip Balm OEM/ODM

- Cooperation Empowerment System: Modular Processes to Quickly Open Up the Entire Product Launch Link